| Welcome, Guest |

You have to register before you can post on our site.

|

| Forum Statistics |

» Members: 3,212

» Latest member: Joshuazef

» Forum threads: 8,052

» Forum posts: 100,243

Full Statistics

|

| Latest Threads |

Valve Springs

Forum: Forum chat...

Last Post: Charles P

1 hour ago

» Replies: 8

» Views: 190

|

What have you done today ...

Forum: Forum chat...

Last Post: David Stepney

3 hours ago

» Replies: 6,769

» Views: 1,399,124

|

Pinion Bearing Locking Ri...

Forum: Wants

Last Post: Steve Jones

Yesterday, 11:29 AM

» Replies: 1

» Views: 38

|

Cause of backfire or popp...

Forum: Forum chat...

Last Post: Peter Naulls

Yesterday, 08:16 AM

» Replies: 13

» Views: 473

|

My own fault, snapped val...

Forum: Forum chat...

Last Post: Andy Bennett

Yesterday, 08:12 AM

» Replies: 10

» Views: 421

|

EOM 610 - 1939 Austin Rub...

Forum: Forum chat...

Last Post: Colintree

29-04-2025, 10:54 PM

» Replies: 0

» Views: 62

|

Mystery Noise

Forum: Forum chat...

Last Post: David Stepney

29-04-2025, 10:42 PM

» Replies: 16

» Views: 515

|

Drive it Day 2025

Forum: Forum chat...

Last Post: phillips

29-04-2025, 07:27 PM

» Replies: 22

» Views: 690

|

Double front shocks

Forum: Forum chat...

Last Post: goodwoodweirdo

29-04-2025, 04:15 PM

» Replies: 3

» Views: 114

|

Lucas SM3/SM5 wiring

Forum: Forum chat...

Last Post: tomcotez

29-04-2025, 02:04 PM

» Replies: 0

» Views: 52

|

|

|

| Ruby steering rack |

|

Posted by: Nigel65 - 24-04-2025, 04:43 PM - Forum: Forum chat...

- Replies (10)

|

|

Hi all,

Anybody got an idea how to get oil into a 1936 Ruby' steering rack? Looks like there's an originol Enots nipple, but try as I might i cannot get anything in there. When I remove the nipple there's something behind it stopping the oil going in. Looks like a metal plate but I'm guessing its the worm drive. I've tried injecting Penrite steering rack oil. Any advice please.

|

|

|

| Latest A7CA insurance matters |

|

Posted by: Association Secretary - 24-04-2025, 09:40 AM - Forum: Forum chat...

- No Replies

|

|

Nick Salmon - interim Insurance Liaison Officer - writes:

Latest insurance matters. Please ensure this information reaches your club membership.

Recent communication between the A7CA and RH Insurance has confirmed that the RH telephone team are aware of the names of the clubs that belong to the A7CA. So if you call RH for a quotation for insurance of an Austin Seven and you are asked for the name of your Austin Seven club, the advisors will know whether the preferential terms accorded to those in A7CA member clubs are applicable.

Also, you may already be aware that A7s insured with RH are normally covered when carrying out non-competitive parade laps at shows and events etc.

RH will also consider obtaining cover for those who want to take part in competitive events or track days.

RH have told the A7CA that: "Due to the wide range of acceptability parameters (ie age of driver, type and location of event, value of vehicle, insurer appetite etc), we are unable to provide definitive guidelines. Applicable charges will also vary depending on the event and insurance company we place the cover with. The preferred approach is therefore for members to call us so that we can assess each case and refer to the insurers."

|

|

|

| My own fault, snapped valve |

|

Posted by: Andy Bennett - 23-04-2025, 08:00 PM - Forum: Forum chat...

- Replies (10)

|

|

Well

If you recall I had a head gasket fail late last year on my 33 RP low compression head and as a result of detecting a depression at the point of failure, I put on a new skimmed head. What I failed to do was test the clearance to the valves. However, all seemed OK, good compression (c 110 to 120 across all 4), and so I seemed to have got away with my error in not testing for clearance.

You can see where this is heading.

For lots of reasons, mainly house renevation reasons, I have only done a couple of hundred miles or so since and nothing since Xmas.

With a local event this weekend I decided to check things out this afternoon. First thing I did was to check head stud torque as I felt it likely things were still settling and very strange that whilst most took a nip up, no 14 took a half turn to 18lb.

Then on running, all was OK for a few minutes and as was about to take a trip around the block it suddenly ran really rough and apparently running on 3. A compression test later and no4 was at 50lb, all others at 120lb.

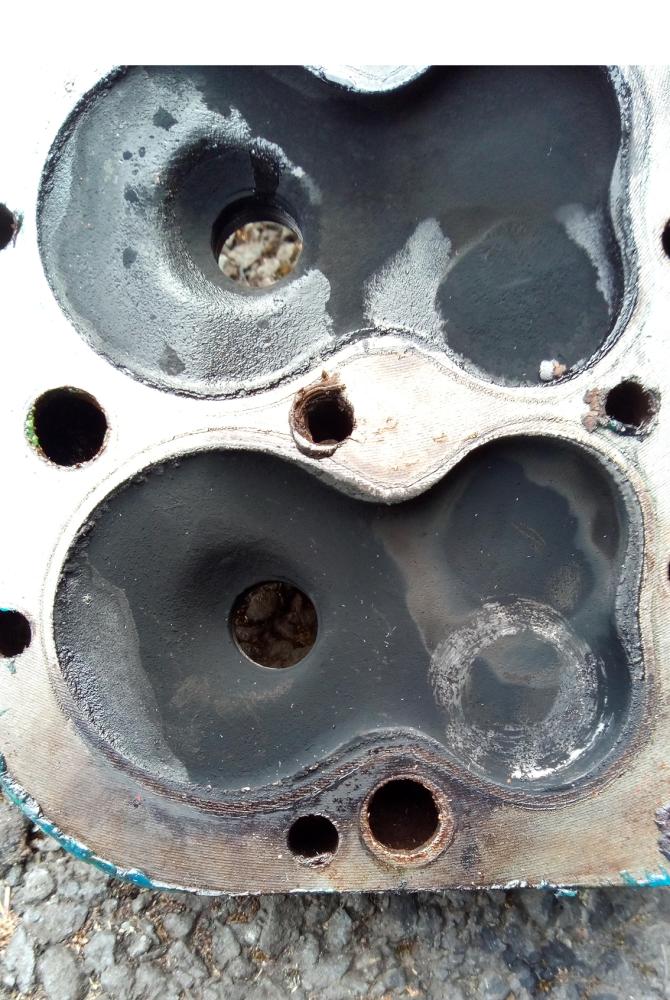

I took off the head and found below:

As you can see cylinder 4 exhaust was clearly making contact with the head and finally snapped. I am guessing it was only just but enough. As I say, some here mentioned the head I was using looked like it was tight on skimming and I just didn't think about testing it out until it was already bolted on. Perhaps my last nip up today was enough to make the inteference. No sign of any other contact.

So, to a day I wasn't expecting to need. I'll go through what I have done so far and what I intend to do, on the principle that I missed something stupid last time I would appreciate a numpty review and a possible save for me doing something else daft.

I had a spare new valve and lapped it in. I put it in and half an hour of swearing later managed to get the collets back in place. Turning over by hand and all seems to run smoothly

Cold the tappet no 8 gap is 6 thou using rule of 9.

I have a replacement head coming hopefully tomorrow whixch looks to be in good condition with lots of clearance to the valves and new gasket etc.

Once it arrives I will turn over by hand to check out the head to valve clearance without the gasket in place by ear and with engineers blue.

Thereafter usual head gasket refit with usual mutliple checks to 18-20lb.

The fact that 14 was relatively loose worries me. It did then nip up easily with no feeling that it was soft. Could the valve hitting the head have rattled it loose as too much of a coincidence that it is closest to the failed valve. I tried to remove it to replace anyway but it is stuck fast and I see a snapped stud to add to my woes if I try too hard.

Advice and comment (notably the bleedin' obvious like I missed last time) appreciated...

|

|

|

| Smiths (magmo) speedometer repair. |

|

Posted by: GM6VXB - 21-04-2025, 07:50 PM - Forum: Forum chat...

- Replies (3)

|

|

Re-building a Smiths Magmo type speedometer, basically swapping parts between my original semi functioning one and a very poor condition one.

So far got all except the milometer working but found the small brass gear that is driven from the worm drive (end of drive cable)

has teeth missing and is BER.

Looking back on old threads it appears these gears are now unobtainium.

'Googling' for similar 20 tooth brass gears does not come up with anything similar. Suspect plastic ones will not be up to the job, but

cannot find similar ones of these either !.

Gear is 20 tooth one, about 9MM diameter, 2MM thick, with a splined hole 4MM diameter. All measurements are approximate.

Anyone ever managed to get replacement gears, not counting removing from a U/S speedometer ?.

Well beyond my capabilites to cut a new gear on a lathe.

Yes I know, run it without the milometer, but it is nice to know how many miles I am doing having done what I thought was

a 30 mile trip which my wife told me was actually 50 miles !.

Martin, GM6VXB

|

|

|

| chummy petrol tap |

|

Posted by: Jeff Blight - 21-04-2025, 09:02 AM - Forum: Forum chat...

- Replies (5)

|

|

Hi the fuel tap on my chummy got very tight so I had it off and lapped it together with some tcut now its alot easier to turn but does not fully turn off I see new ones are availably and expensive any one got any tips to whats Happening?Thanks Jeff Blight

|

|

|

| Ignition switch |

|

Posted by: Pint Pot - 20-04-2025, 09:03 PM - Forum: Forum chat...

- Replies (10)

|

|

Good evening all, I am a comlete duffer where electrics are concerned and need some help. The switch on my 7 diintegrated and the only replacement I could get is one without the charging options - before I remove the many wires from the original switch can somone please explain what they work. I have diagram in a Pitman`s book but while the terminals have various codes allocated to them it doesn`t explain what they actually do, any help greatly appreciated.

|

|

|

| Headlight Wiring |

|

Posted by: iandecjak - 20-04-2025, 02:46 PM - Forum: Forum chat...

- Replies (3)

|

|

Am installing headlights into Ruby Mk2 and am confused as to the wiring terminal connections. Each headlight has a pos, neg and earth leads at bulb end with spade end connectors which appear to all fit onto dip switch in the engine bay. Looking at the wiring diagram I cannot work out what goes where.

Not sure which dip switch terminal does what at the 3,6 and 9 oclock positions (viewed from engine bay); would really appreciate some guidance on how to wire it all up?

|

|

|

|