23-04-2025, 08:00 PM

Well

If you recall I had a head gasket fail late last year on my 33 RP low compression head and as a result of detecting a depression at the point of failure, I put on a new skimmed head. What I failed to do was test the clearance to the valves. However, all seemed OK, good compression (c 110 to 120 across all 4), and so I seemed to have got away with my error in not testing for clearance.

You can see where this is heading.

For lots of reasons, mainly house renevation reasons, I have only done a couple of hundred miles or so since and nothing since Xmas.

With a local event this weekend I decided to check things out this afternoon. First thing I did was to check head stud torque as I felt it likely things were still settling and very strange that whilst most took a nip up, no 14 took a half turn to 18lb.

Then on running, all was OK for a few minutes and as was about to take a trip around the block it suddenly ran really rough and apparently running on 3. A compression test later and no4 was at 50lb, all others at 120lb.

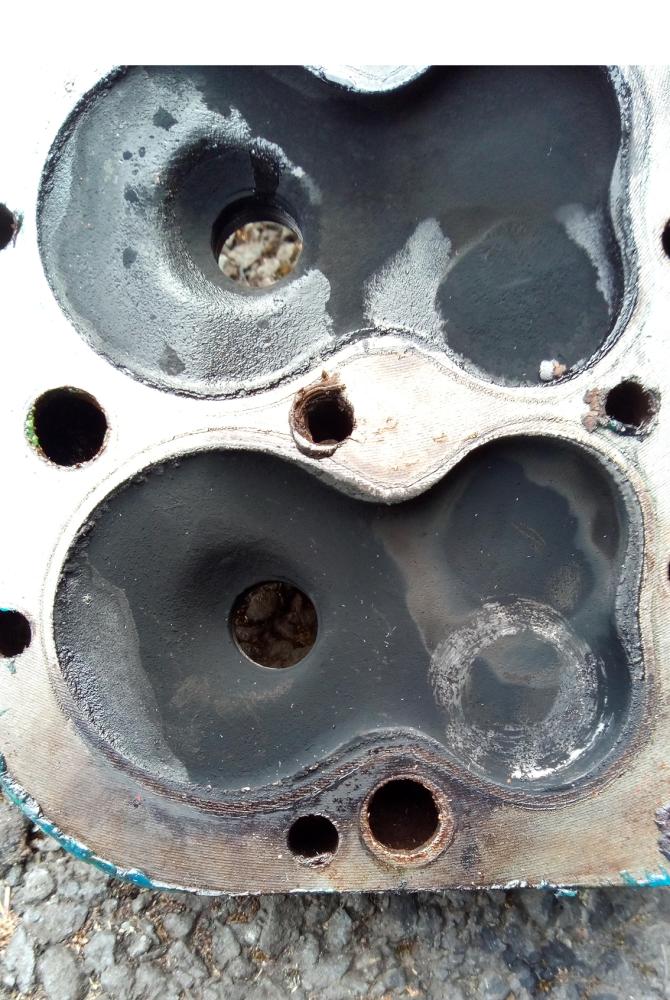

I took off the head and found below:

As you can see cylinder 4 exhaust was clearly making contact with the head and finally snapped. I am guessing it was only just but enough. As I say, some here mentioned the head I was using looked like it was tight on skimming and I just didn't think about testing it out until it was already bolted on. Perhaps my last nip up today was enough to make the inteference. No sign of any other contact.

So, to a day I wasn't expecting to need. I'll go through what I have done so far and what I intend to do, on the principle that I missed something stupid last time I would appreciate a numpty review and a possible save for me doing something else daft.

I had a spare new valve and lapped it in. I put it in and half an hour of swearing later managed to get the collets back in place. Turning over by hand and all seems to run smoothly

Cold the tappet no 8 gap is 6 thou using rule of 9.

I have a replacement head coming hopefully tomorrow whixch looks to be in good condition with lots of clearance to the valves and new gasket etc.

Once it arrives I will turn over by hand to check out the head to valve clearance without the gasket in place by ear and with engineers blue.

Thereafter usual head gasket refit with usual mutliple checks to 18-20lb.

The fact that 14 was relatively loose worries me. It did then nip up easily with no feeling that it was soft. Could the valve hitting the head have rattled it loose as too much of a coincidence that it is closest to the failed valve. I tried to remove it to replace anyway but it is stuck fast and I see a snapped stud to add to my woes if I try too hard.

Advice and comment (notably the bleedin' obvious like I missed last time) appreciated...

If you recall I had a head gasket fail late last year on my 33 RP low compression head and as a result of detecting a depression at the point of failure, I put on a new skimmed head. What I failed to do was test the clearance to the valves. However, all seemed OK, good compression (c 110 to 120 across all 4), and so I seemed to have got away with my error in not testing for clearance.

You can see where this is heading.

For lots of reasons, mainly house renevation reasons, I have only done a couple of hundred miles or so since and nothing since Xmas.

With a local event this weekend I decided to check things out this afternoon. First thing I did was to check head stud torque as I felt it likely things were still settling and very strange that whilst most took a nip up, no 14 took a half turn to 18lb.

Then on running, all was OK for a few minutes and as was about to take a trip around the block it suddenly ran really rough and apparently running on 3. A compression test later and no4 was at 50lb, all others at 120lb.

I took off the head and found below:

As you can see cylinder 4 exhaust was clearly making contact with the head and finally snapped. I am guessing it was only just but enough. As I say, some here mentioned the head I was using looked like it was tight on skimming and I just didn't think about testing it out until it was already bolted on. Perhaps my last nip up today was enough to make the inteference. No sign of any other contact.

So, to a day I wasn't expecting to need. I'll go through what I have done so far and what I intend to do, on the principle that I missed something stupid last time I would appreciate a numpty review and a possible save for me doing something else daft.

I had a spare new valve and lapped it in. I put it in and half an hour of swearing later managed to get the collets back in place. Turning over by hand and all seems to run smoothly

Cold the tappet no 8 gap is 6 thou using rule of 9.

I have a replacement head coming hopefully tomorrow whixch looks to be in good condition with lots of clearance to the valves and new gasket etc.

Once it arrives I will turn over by hand to check out the head to valve clearance without the gasket in place by ear and with engineers blue.

Thereafter usual head gasket refit with usual mutliple checks to 18-20lb.

The fact that 14 was relatively loose worries me. It did then nip up easily with no feeling that it was soft. Could the valve hitting the head have rattled it loose as too much of a coincidence that it is closest to the failed valve. I tried to remove it to replace anyway but it is stuck fast and I see a snapped stud to add to my woes if I try too hard.

Advice and comment (notably the bleedin' obvious like I missed last time) appreciated...

Enjoy yourself, it's later than you think!