18-08-2022, 07:17 PM

I have a 26VA carb on my 33 RP.

After an enforced layup I had problems with running on anything other than full choke.

I replaced fuel, slight improvement, but still poor running.

I then blew through the jets with compressed air, again slightly better but still poor.

I couldn't get the jets out so tried poking a very fine needle through jets. Met some resistance, again slightly better, now running half choke but no better.

So, in accepting that the problem likely lay somewhere in the jets, I dug out a spare carb I had purchased as refurbished by Holmesdale Sevens.

So, here is the crux of my question.

I recall some information a while ago about some subtle differences in 26VA carbs and reasons not to mix bowls.

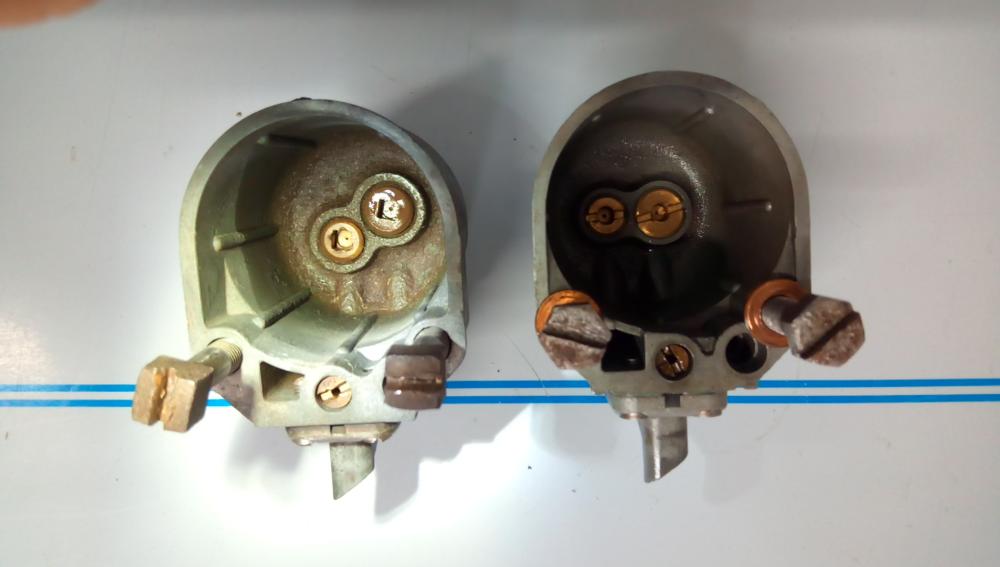

The bowl on the carb on my car is subtly different to that on the spare carb, in that the jets are in slightly different positions and the resulting moulding on the base is different. From what I can tell the rest is identical, the emulsion block and all connections look to be the same. I therefore bolted it on and the car sprung into life and ran as sweet as could be, revved if anything better than it has in a long time. Problem apparently solved.

I appreciate that the immediate comment might be: it fits, it doesn't leak and it runs well, enjoy. Also some might say well just replace the whole carb.

But, I don't want to break the banjo joint or the manifold joint if I don't have to. But, there is the niggling comment in my mind that there is a reason not to mix different bowls on different carbs.

Any of this making sense?

After an enforced layup I had problems with running on anything other than full choke.

I replaced fuel, slight improvement, but still poor running.

I then blew through the jets with compressed air, again slightly better but still poor.

I couldn't get the jets out so tried poking a very fine needle through jets. Met some resistance, again slightly better, now running half choke but no better.

So, in accepting that the problem likely lay somewhere in the jets, I dug out a spare carb I had purchased as refurbished by Holmesdale Sevens.

So, here is the crux of my question.

I recall some information a while ago about some subtle differences in 26VA carbs and reasons not to mix bowls.

The bowl on the carb on my car is subtly different to that on the spare carb, in that the jets are in slightly different positions and the resulting moulding on the base is different. From what I can tell the rest is identical, the emulsion block and all connections look to be the same. I therefore bolted it on and the car sprung into life and ran as sweet as could be, revved if anything better than it has in a long time. Problem apparently solved.

I appreciate that the immediate comment might be: it fits, it doesn't leak and it runs well, enjoy. Also some might say well just replace the whole carb.

But, I don't want to break the banjo joint or the manifold joint if I don't have to. But, there is the niggling comment in my mind that there is a reason not to mix different bowls on different carbs.

Any of this making sense?

Enjoy yourself, it's later than you think!