Joined: Aug 2017 Posts: 691 Threads: 37

Reputation:

1

Location: The Scottish Border

They say that the lightest, fastest Supermaribe Spitfires

Were those that had no paint, just bare polished aluminium

And flush rivets.

To gain an extra 1mph top speed I have followed this design

feature to its logical conclusion on my AllAlloyCup.

I found these neat little stainless 4mm Domed coach bolts

on EBay and they will surely help with the streamlining?

Handy for those fixings inside the bonnet compartment.

Regards

Bill G

Based near the Scottish Border,

Joined: Aug 2017 Posts: 691 Threads: 37

Reputation:

1

Location: The Scottish Border

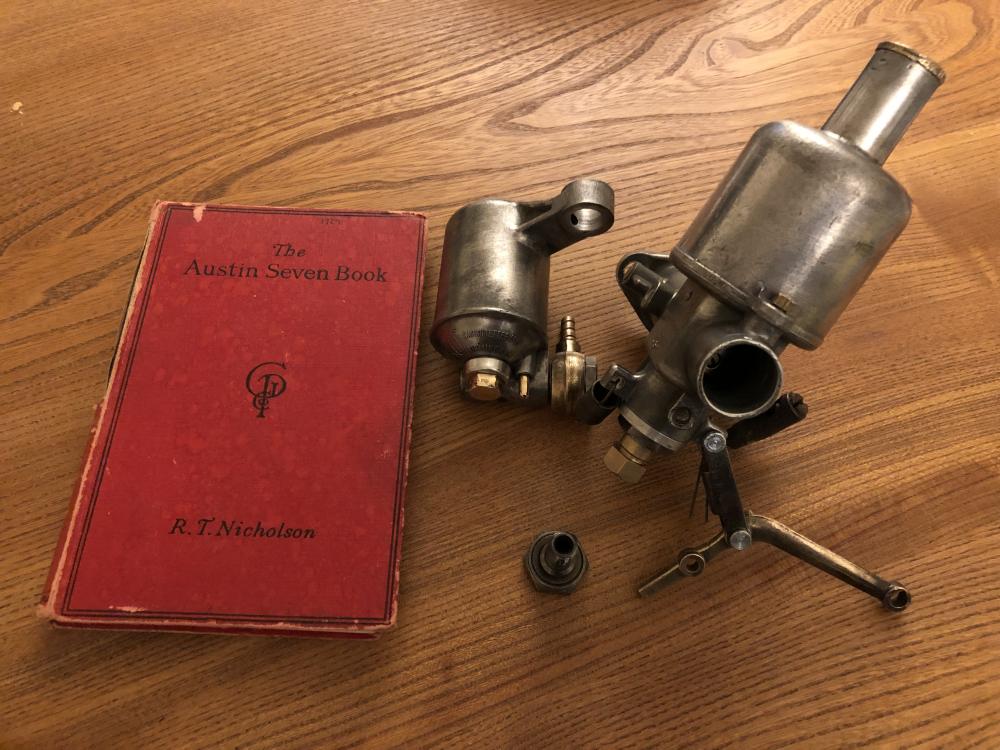

Just stripped and rebuilt the OM SU and will fit the AN needle as advised plus have sorted out

A neat petrol filter. Waiting on some pipe bits to

To finish off.

I’ve an original tank , but unsure whether to coat the inside,

Or rumble some ball bearings in it, or let sleeping dogs lie?

I changed the filler cap to a screw on one.

Any suggestions about the inside of the tank.

Plus sent the rad shell off to the platers, so better start

Saving up!

Regards

Bill G

Based near the Scottish Border,

Joined: Aug 2017 Posts: 1,230 Threads: 33

Reputation:

6

Location: Salop

Car type: '28 GE Cup. '28 AD Chummy '30 RL Saloon. '34 RP Saloon. Too Many toys!

Are you aluminium plating the cowl Bill?. That would look good.

One fabricated in Ali would be even sexier.

Joined: Aug 2017 Posts: 691 Threads: 37

Reputation:

1

Location: The Scottish Border

05-02-2019, 01:20 PM

(This post was last modified: 05-02-2019, 01:23 PM by AllAlloyCup.)

Hi Hedd

By the cowl, do you mean the fabric cover that original GE Cups used?

I am planning to do machine turning on the bulkhead which is an

extra bit of bling I’ve been contemplating as well as replacing the fabric cowl

With an easily shaped alloy part to replace it?

I have a shrinker stretcher and quite a lot of alloy sheet left over so I can probably

manage most of it myself. Would need to see how easy it would be to remove

In case I needed to do work under it though.

Will make a cardboard one, like the dozens of patterns I’ve made since the start!!!

Regards

Bill G

Perhaps by cowl you meant the rad shell?

No it will be nickelled as it’s a steel chummy one.

At some stage I may paint the car... but not this year

Regards

Bill G

Based near the Scottish Border,

Joined: Aug 2017 Posts: 691 Threads: 37

Reputation:

1

Location: The Scottish Border

Joined: Mar 2015 Posts: 5,195 Threads: 223

Reputation:

59

Location: Scotchland

Bill,

Have you considered fitting a pump?

Joined: Aug 2017 Posts: 691 Threads: 37

Reputation:

1

Location: The Scottish Border

10-02-2019, 08:20 PM

(This post was last modified: 25-05-2019, 11:18 AM by AllAlloyCup.)

Hi Ruaridh

The level at the jet head is well below the bottom of the tank

And numerous posts have said that this SU set up can work reliably

As long as the tank has a fair level of fuel in it.

This OM has a throat slightly less than 1” so I’m happy to try out this

Arrangement with the AN needle.

I had a daft thought that the other way to ensure a full fuel feed

was to fit an Ulster type air pump? If need be an SU pump can be retrofitted.

Has anyone tried this out on a Chummy with a non cooking engine.

Eg standard valves and camshaft , but alloy HC head, lightweight pistons

and steel crank, I’m not planning to do racing!

If I can keep up with Jim H or Malcolm P I’ll be happy enough!

Regards

Bill G

Based near the Scottish Border,

Joined: Aug 2017 Posts: 424 Threads: 30

Reputation:

7

Location: Wellington, NZ

I have been looking at how to do my throttle linkage too and I think I can do a simple linkage similar to yours (am using the same throttle linkage across the firewall but an DD SU) as long as I get the lengths right. You can buy the ball linkages of various lengths from Burlen new still. They weren't hugely expensive either. I was going to use one of the little clamp on brass arms on the throttle spindle on the carb maybe.

Simon

Joined: Aug 2017 Posts: 691 Threads: 37

Reputation:

1

Location: The Scottish Border

10-02-2019, 09:12 PM

(This post was last modified: 25-05-2019, 11:19 AM by AllAlloyCup.)

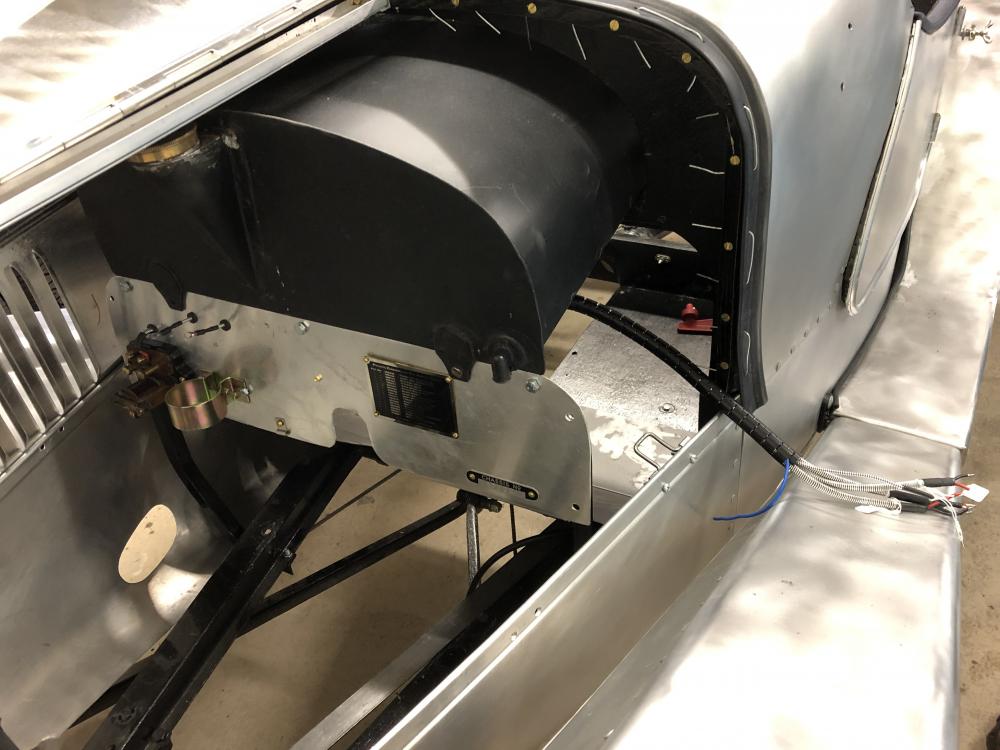

Hi Simon

I have a brass cast lever on the butterfly spindle

and I’ve bent the end of throttle cross shaft so that

it’s roughly under the end of the brass lever.

There’s not a huge amount of travel on the throttle pedal

and I just need to make sure that flooring the pedal approximates

to maximum opening of the butterfly, so probably will need to

Sit the engine in the chassis, fit the floor boards and bulkhead and then

Cut a suitable short throttle control rods with nice movement at each end with

No stiffness and effective return spring( already bought)

Will post pics when I’ve figured it out!!

Pls post photos if yours is set up.

Regards

Bill G

Based near the Scottish Border,