Joined: Aug 2017 Posts: 172 Threads: 1

Reputation:

3

Location: Richmond, Texas, USA

I remember looking at this 60-ish years ago, and wondering where the oil went.

Maybe you drill some holes?

Joined: Aug 2017 Posts: 1,808 Threads: 99

Reputation:

21

Must admit, I dont get it.

It looks like another stupid idea from the idiots companion.

I can see the suggestion of supporting the centre main? But does it really.

It looks to be friction fit against the centre main. And if it is. Surly you dont need to be putting any upward force on the centre main. It would just push the inline bearings, out of line.

Tony.

Joined: Aug 2017 Posts: 1,725 Threads: 47

Reputation:

25

Location: Auckland NZ

Car type: 36 Nippy, 31 RM, 38 Special, 24 Works Rep

No Tony, it was the SBG then Design for competition and then The Companion, I have all three publications, Design for competition is by far the more comprehensive from a special builders perspective. I think it fair to say that The Companion is not strictly aimed at special builders which the other's were, and as with all 750 MC publications the articles were very much the opinion of the writer, much like here, so you take more notice of those who have proven track records and make up your own mind rather than blindly take things as gospel.

Black Art Enthusiast

Joined: Jun 2018 Posts: 560 Threads: 100

Reputation:

2

Thank you, Ritchie, for posting this.

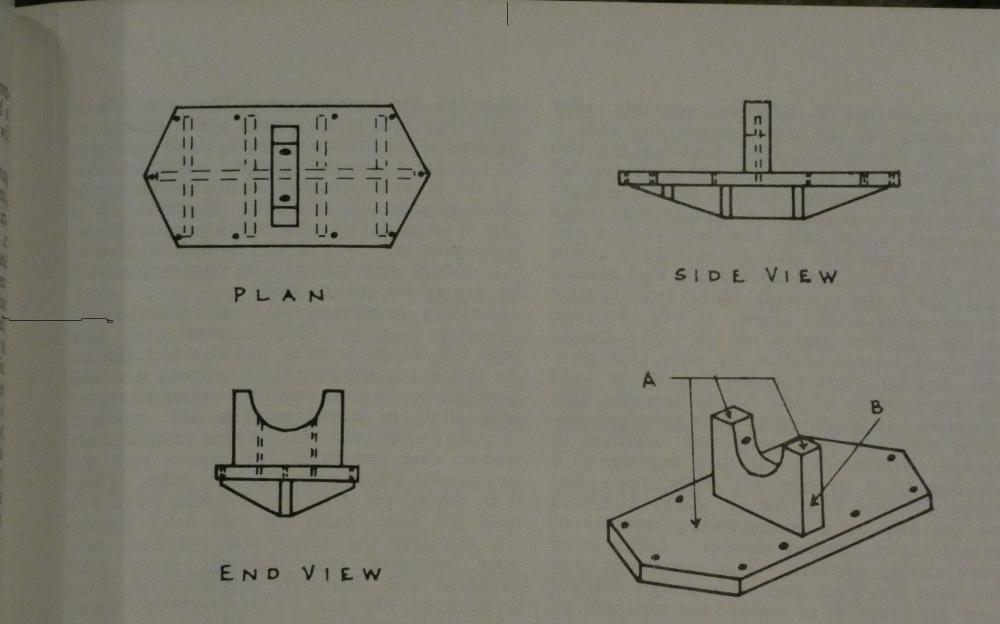

I can see the logic, assuming that the centre bearing is restrained from flexing downwards by the support on the plate. Somehow, though, I can imagine it causing other problems by trying to push the centre bearing upwards too much if the whole set up is not machined and fitted extremely accurately.

I think that I will stick to the advice from the old Speedex site for setting up the centre bearing when I finally get to that stage.

Regards,

Jamie.

Joined: Aug 2017 Posts: 651 Threads: 29

Reputation:

7

I've only worked on one 3 brg engine,and checking the centre bearing alignment it was within around .001". The general consensus of these engines was that the centre bearing was often out of line,this and insufficient oil to the centre main meant a short life.

One chap I knew made a new centre bearing undersize and line bored it when all clamped up with the block.

A couple of tricks I was told were ,To use 2 of the offside bolts, ( The ones that bolt the block down ) and drill the block to suit (now a 9 bolt block )

Blank the oil feed past the centre main where it feeds the camshaft bushes and drill a couple of small holes into the bushes from above .

Check the crank centre webs for cracks ,the copper pipe to the centre bearing and use an oversized oil pump.

They do make a nice smooth engine.

Joined: Mar 2015 Posts: 5,542 Threads: 232

Reputation:

71

Location: Scotchland

A properly rebuilt three bearing engine in standard form is sublime and, in my experience, no more or less reliable than a two bearing engine.

A poorly built three bearing engine is another matter entirely.

My rule of thumb is that I will only rebuild a three bearing engine if it comes in complete - so that I can see what has gone wrong as I break it down. I won't touch a dismantled one.

Joined: Aug 2017 Posts: 60 Threads: 5

Reputation:

0

Location: Christchurch NZ

I had a look through the Austin Seven Companion (the green book) and Tony Press is quite right, the Jack Cotton article didn't make the cut from the Design for Competition book (also green). I agree that this doesn't inspire confidence. Mr Cotton did say that the modification cured the big-end failures, although he changed the centre-main bearing every 2 or 3 races and fitted a higher capacity oil pump.

Jack French has an article in the Companion from Nov 1959 where he discusses the 3 bearing engine. Like Austin in the Shed and Jack Cotton he recommends line-boring an under-size centre-main bearing. Jack French advocates machining several and replacing them at 5000 mile intervals citing Colin Chapman's experience with Lotus 3 in 1951

Joined: Aug 2017 Posts: 3,493 Threads: 108

Reputation:

30

Location: Darkest Bedfordshire

1985D P7 figs 2 - 3 + a decent crank : sorted.