05-01-2020, 07:28 PM

(This post was last modified: 05-01-2020, 07:39 PM by Andy Cawley.)

I am reassembling my magneto engine after breaking the crank and am fitting a new 1 1/8" Pheonix crank. I had quite a delay waiting for the crank and the memory has faded of the disassembly and I'm having difficulty remembering precisely how it all goes together and also whether or not any bits were missing when I took it all apart.

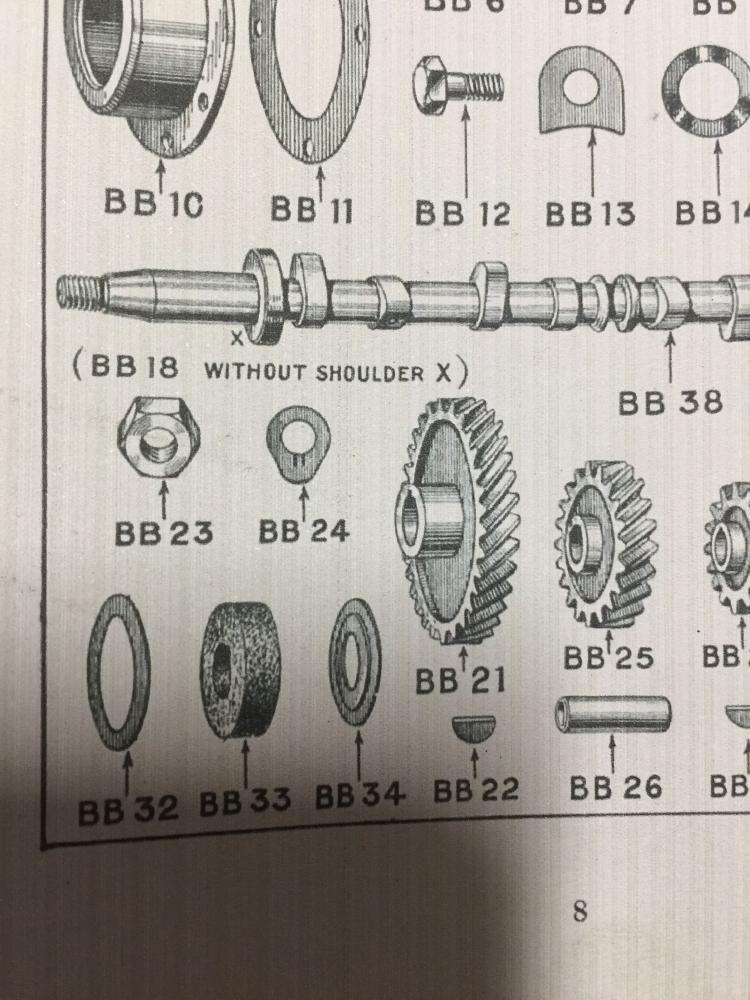

My current puzzle is the importance of item BB34 described in the spares list as a plate. It appears the purpose of this item is to protect the ball bearing from the magneto felt oil seal.

I cannot find the plate in my box of bits .

.

I will probably have to make one but I have no information as to the dimensions and looking at the picture in the spares list it is not exactly a simple disc of uniform thickness.

Can anybody help out.

I would have posted a photo but couldn't work out how to, sad isn't it?

Could I just fit a sealed bearing and leave out the felt seal. If I did this would I need to make a spacer to replace the felt seal ( I have bought a new seal)?

My current puzzle is the importance of item BB34 described in the spares list as a plate. It appears the purpose of this item is to protect the ball bearing from the magneto felt oil seal.

I cannot find the plate in my box of bits

.

.I will probably have to make one but I have no information as to the dimensions and looking at the picture in the spares list it is not exactly a simple disc of uniform thickness.

Can anybody help out.

I would have posted a photo but couldn't work out how to, sad isn't it?

Could I just fit a sealed bearing and leave out the felt seal. If I did this would I need to make a spacer to replace the felt seal ( I have bought a new seal)?