14-11-2019, 11:17 AM

Not strictly Austin 7, but may be of interest to the forum. I hope to be able to complete some A7 related machining at some stage!

Having reached semi-retirement recently, I decided to investigate some of the sheds in the garden and rediscovered a milling machine, pushed to the back of the largest shed years ago. Yesterday, I moved the machine into the garage (not an easy job I might add), ready to start work on it as a background restoration project this winter.

I bought this machine twenty plus years ago in a fit of youthful ambition but it has lain, partially stripped ever since, as dismemberment was the only practical means to transport it. Fully assembled, it must weigh in at 700 kilos or more. It has spent a long time in the shed and has gone fairly rusty as a result.

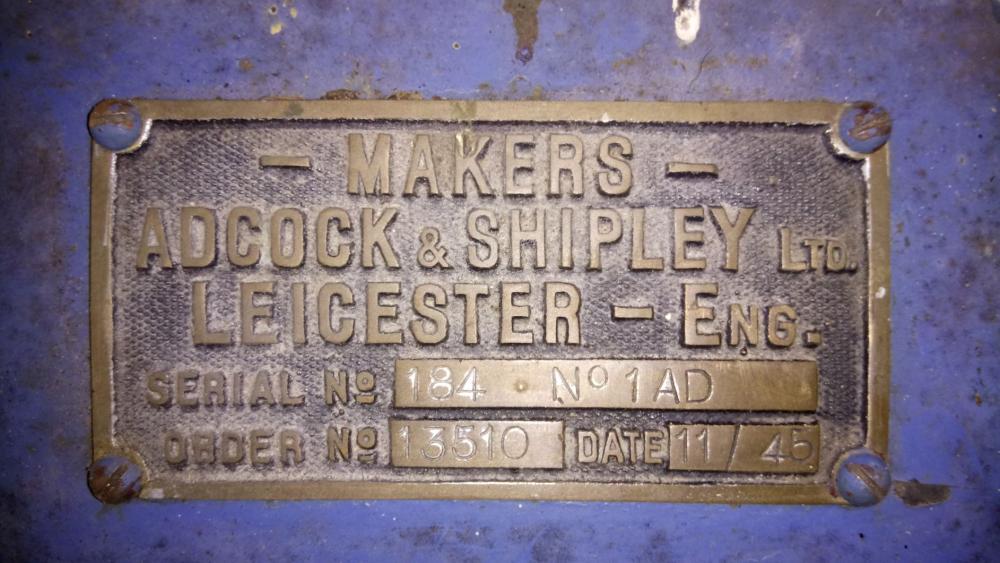

It’s an Adcock & Shipley 1AD, manual toolroom mill, with vertical and horizontal capability, manufactured in 1945. Unfortunately, because of its age, it has obsolete taper fittings, 1 3/8” non-stick, which was a wartime UK standard, subsequently replaced with metric international standard tapers. I didn’t realize this until after I had bought it and tooling is very scarce apparently; I’ve never come across anything in the last twenty years that will fit. Caveat emptor! However, I have the horizontal arbour and I have turned up an adapter that will allow 30INT taper tooling to be used in the vertical head, probably with reduced accuracy. There is also the possibility of a Japanese CNC taper that may fit (BT35). I have acquired quite a lot of horizontal cutters and a selection of end mills over the years so I now have a reasonable amount of tooling. I will need to add a dividing head at some stage.

It’s still on machine skids in the garage so that I can move it while I give it a burnish with paraffin and wire wool to get rid of the surface rust and a coat of paint. I can then reassemble and wire it up with a single-phase motor and modern switch gear as all the electrics have been stripped out. It will also need a suds system adding.

Interestingly, there’s a video on YouTube of a working A&S 1AD, it’s only 2 serial numbers different to mine and was produced for the same order!

Having reached semi-retirement recently, I decided to investigate some of the sheds in the garden and rediscovered a milling machine, pushed to the back of the largest shed years ago. Yesterday, I moved the machine into the garage (not an easy job I might add), ready to start work on it as a background restoration project this winter.

I bought this machine twenty plus years ago in a fit of youthful ambition but it has lain, partially stripped ever since, as dismemberment was the only practical means to transport it. Fully assembled, it must weigh in at 700 kilos or more. It has spent a long time in the shed and has gone fairly rusty as a result.

It’s an Adcock & Shipley 1AD, manual toolroom mill, with vertical and horizontal capability, manufactured in 1945. Unfortunately, because of its age, it has obsolete taper fittings, 1 3/8” non-stick, which was a wartime UK standard, subsequently replaced with metric international standard tapers. I didn’t realize this until after I had bought it and tooling is very scarce apparently; I’ve never come across anything in the last twenty years that will fit. Caveat emptor! However, I have the horizontal arbour and I have turned up an adapter that will allow 30INT taper tooling to be used in the vertical head, probably with reduced accuracy. There is also the possibility of a Japanese CNC taper that may fit (BT35). I have acquired quite a lot of horizontal cutters and a selection of end mills over the years so I now have a reasonable amount of tooling. I will need to add a dividing head at some stage.

It’s still on machine skids in the garage so that I can move it while I give it a burnish with paraffin and wire wool to get rid of the surface rust and a coat of paint. I can then reassemble and wire it up with a single-phase motor and modern switch gear as all the electrics have been stripped out. It will also need a suds system adding.

Interestingly, there’s a video on YouTube of a working A&S 1AD, it’s only 2 serial numbers different to mine and was produced for the same order!

![[Image: asno1.jpg]](http://www.lathes.uk/asno1.jpg)

![[Image: asno2.jpg]](http://www.lathes.uk/asno2.jpg)

![[Image: asno3.jpg]](http://www.lathes.uk/asno3.jpg)

![[Image: asno4.jpg]](http://www.lathes.uk/asno4.jpg)